- Home Page

- Company Profile

-

Our Products

- Aluminium Coils

- Aluminum Products

- Aluminum Bars

- Aluminium Pipes and Tubes

- Aluminium Sheets and Plates

- Nickel Alloys

- Copper Nickel

- Aluminium Round Bars

- Aluminium Aerospace Materials

- Aluminium Structures

- Aluminium Tread-Raised-Checkered Sheets

- Aluminium Defense Materials

- Aluminium Foil

- Aluminium Forgings

- Aluminium Circles

- Aluminium Pipe Fittings

- Aluminium Forged Fittings

- Aluminium Flanges

- Aluminium Fasteners

- Aluminium Marine Materials

- Copper Nickels

- Alloy series

- Insulation Tapes

- Contact Us

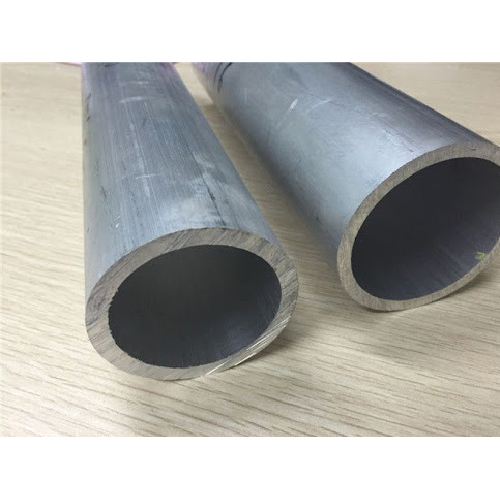

6063 Extruded Aluminium Tubing

Product Details:

- Product Type Aluminum Tube

- Shape Round

- Grade 2024, 5083, 5086, 6061, 6063, 7075

- Surface Treatment Mill finish / Brush polish

- Color Gray

- Warranty 1 Year

- Click to View more

X

6063 Extruded Aluminium Tubing Price And Quantity

- 100 Kilograms

6063 Extruded Aluminium Tubing Product Specifications

- Gray

- Mill finish / Brush polish

- 1 Year

- Round

- 2024, 5083, 5086, 6061, 6063, 7075

- Aluminum Tube

6063 Extruded Aluminium Tubing Trade Information

- 1000 Kilograms Per Day

- 2-4 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

6063 Extruded Aluminium Tubing is a popular material used in a wide range of applications, thanks to its combination of excellent corrosion resistance, good strength-to-weight ratio, and easy machinability.This alloy is particularly favored for its extrudability, making it ideal for tubing and structural applications. 6063 Extruded Aluminium Tubing is primarily made from Aluminum Alloy 6063, which is part of the 6000 series of alloys, known for their magnesium and silicon content. Its ability to be extruded into complex shapes, combined with its ability to be anodized and finished attractively, makes it a top choice for a variety of industries requiring a balance of strength, lightweight, and aesthetic appeal.

Versatile Aluminium Tubing Solutions

Our round extruded aluminium tubing is engineered for both strength and adaptability, catering to multiple industry needs. With several grade choices, each tube offers unique mechanical benefits, making them suitable for applications ranging from construction to automotive manufacturing. The polished or mill finish options allow for both aesthetic and functional uses. The tubes are made to meet international standards, ensuring lasting performance and reliability in every sector.

Premium Quality and Assurance

As a trusted manufacturer, exporter, and supplier from India, we guarantee the quality of every aluminium tube with a 1-year warranty. Our strict quality control processes and attention to detail during production ensure that you receive only the most precise and consistent products, no matter the grade or surface treatment selected.

FAQ's of 6063 Extruded Aluminium Tubing:

Q: How is 6063 extruded aluminium tubing manufactured?

A: 6063 extruded aluminium tubing is produced by heating aluminium billets and forcing them through a die of the desired round shape using high pressure. The process ensures consistent diameter and surface finish, available in grades such as 2024, 5083, 5086, 6061, 6063, and 7075, followed by surface treatments like mill finish or brush polish.Q: What surface treatments are available for these aluminium tubes?

A: Our aluminium tubing can be supplied with either a mill finish or a brush polish. Mill finish provides a natural, smooth appearance, while brush polish adds a refined, slightly textured surface for enhanced aesthetics and corrosion resistance.Q: When should I choose a specific aluminium grade?

A: Selecting a grade depends on your project requirements. For example, 2024 and 7075 are ideal for high-strength applications, while 5083 and 5086 are preferred for marine environments due to superior corrosion resistance. 6061 and 6063 offer excellent weldability and general-purpose utility.Q: Where can these extruded aluminium tubes be used?

A: Our round aluminium tubes serve a broad range of industries, including construction, automotive, marine, aerospace, and furniture manufacturing. Their durability and adaptability make them suitable for both structural and decorative purposes.Q: What is the benefit of the 1-year warranty?

A: The one-year warranty on all tubing ensures peace of mind, covering manufacturing defects and quality issues. It reflects our commitment to delivering dependable products that meet your expectations.Q: How can I order extruded aluminium tubing from India?

A: You can place orders directly through our website, by contacting our sales team, or via our authorized distributors worldwide. We support domestic and international shipping, ensuring timely delivery and quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese