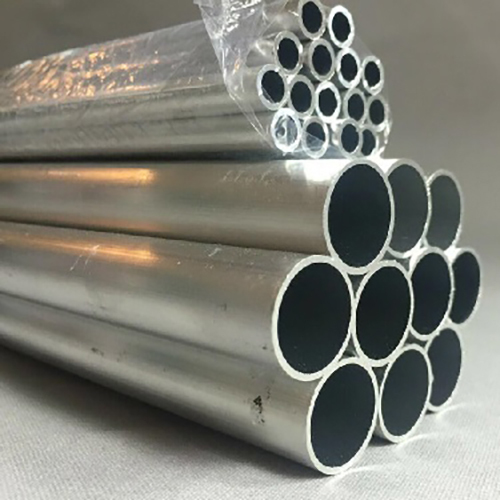

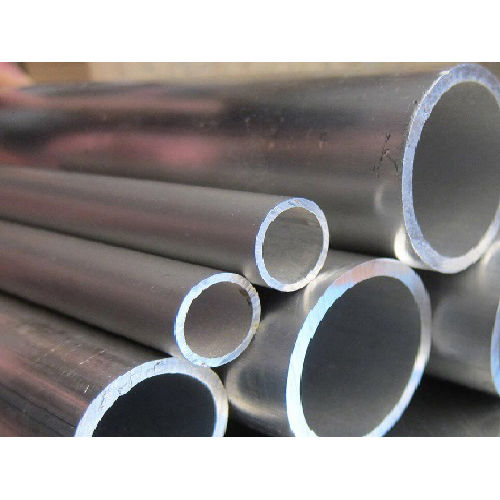

2014 Extruded Aluminium Tubing

350 आईएनआर/Kilograms

उत्पाद विवरण:

- प्रॉडक्ट टाइप Aluminum Tube

- शेप

- ग्रेड 2024, 5083, 5086, 6061, 6063, 7075

- सतह का उपचार

- रंग Gray

- वारंटी 1 Year

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- 1 Year

- 2024, 5083, 5086, 6061, 6063, 7075

- Gray

- Aluminum Tube

व्यापार सूचना

- प्रति दिन

- दिन

- , , , , , , , ,

उत्पाद वर्णन

Specifications

- Transportation industry

- Marine industry

- Solar and renewable Energy

- Building and construction (both commercial and residential)

- Military and Defense

- Electrical bus conductors

- Compressed gas storage

Versatile Material Options

Choose from leading aluminium grades such as 2024, 5083, 5086, 6061, 6063, and 7075 to match your project requirements. Each grade offers distinct mechanical properties, ensuring optimal performance for structural, marine, aerospace, and automotive applications.

Superior Surface Treatment

Our aluminium tubing is available with two primary surface treatments-mill finish for a clean, natural look, and brush polish for an enhanced aesthetic and extra protection. Both finishes offer excellent resistance to corrosion and wear, ideal for demanding environments.

FAQ's of 2014 Extruded Aluminium Tubing:

Q: How is the 2014 Extruded Aluminium Tubing manufactured?

A: The tubing is produced through an extrusion process, where high-grade aluminium billets are pushed through a precisely shaped die to create seamless, round tubes. Surface finishes like mill finish or brush polish are then applied for improved appearance and performance.Q: What are the primary uses of this aluminium tubing?

A: This tubing is widely used in industries such as aerospace, shipbuilding, transportation, construction, and engineering, due to its strength, lightweight character, and corrosion resistance. The round shape makes it especially suitable for frameworks, railings, and fluid transfer systems.Q: When can I expect delivery after placing an order?

A: Delivery times depend on your location and order size. Typically, orders from within India are dispatched within 7-10 business days, while international shipments may require additional transit time. Please contact us for detailed shipping estimates.Q: Where is the aluminium tubing supplied from?

A: Our aluminium tubing is manufactured and supplied from our facilities in India. As an established exporter, manufacturer, and supplier, we serve both the Indian market and international clients.Q: What processes are involved in ensuring quality and warranty?

A: The tubing undergoes stringent quality inspections throughout production, from raw material sourcing to surface treatment and dimensional accuracy. We offer a 1-year warranty against manufacturing defects, supporting our commitment to quality assurance.Q: How do the different aluminium grades benefit various applications?

A: Each aluminium grade excels in different scenarios. For example, 2024 and 7075 provide high strength for aerospace, while 5083 and 5086 are excellent in marine environments. 6061 and 6063 offer versatile uses for construction and general engineering.Q: Is technical support available for custom applications or selection advice?

A: Yes, our expert team is available to assist with technical queries, product selection, and custom application solutions to ensure you receive the most suitable aluminium tubing for your specific requirements.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese